Description

Options for PLT-10 Point Load Tester

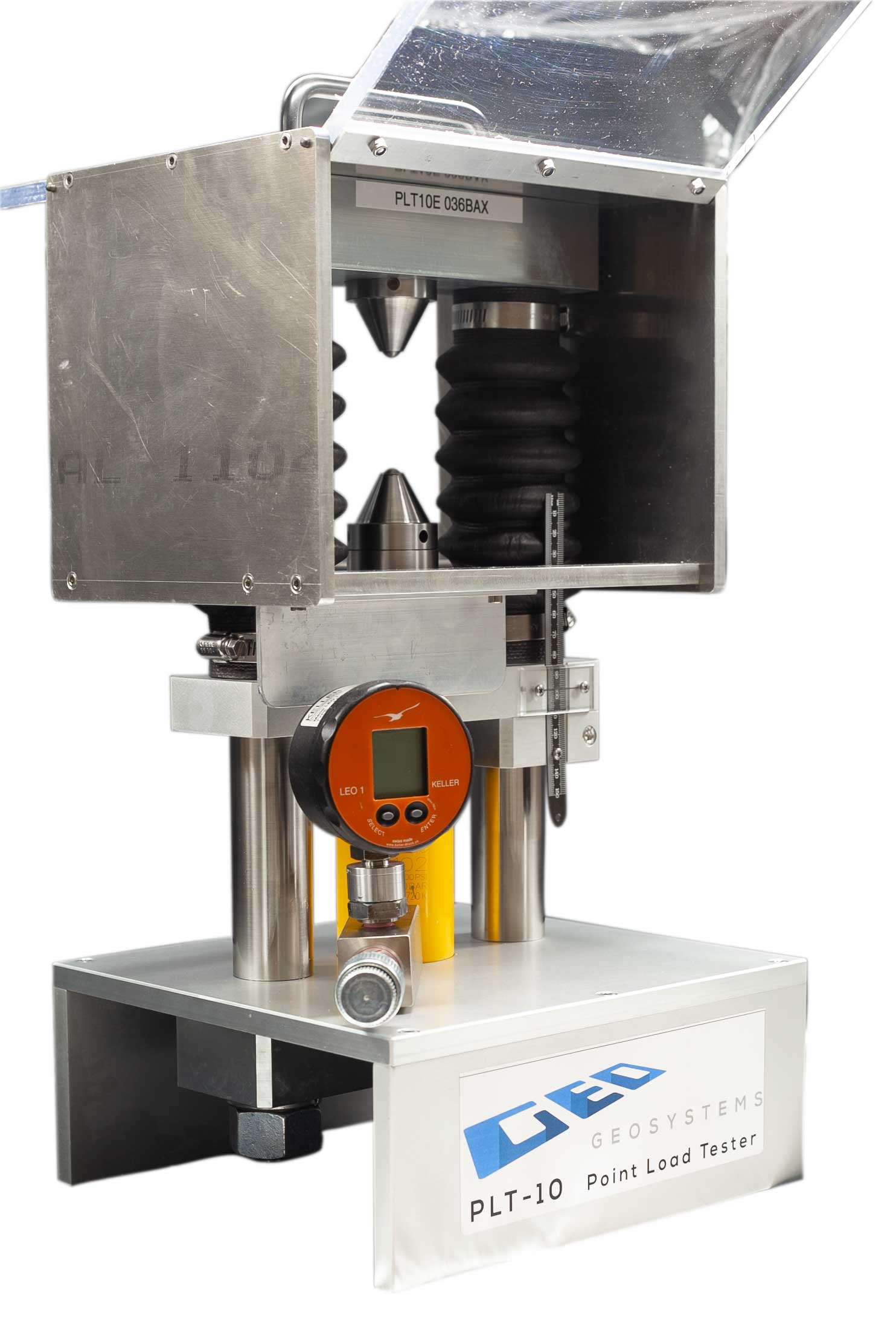

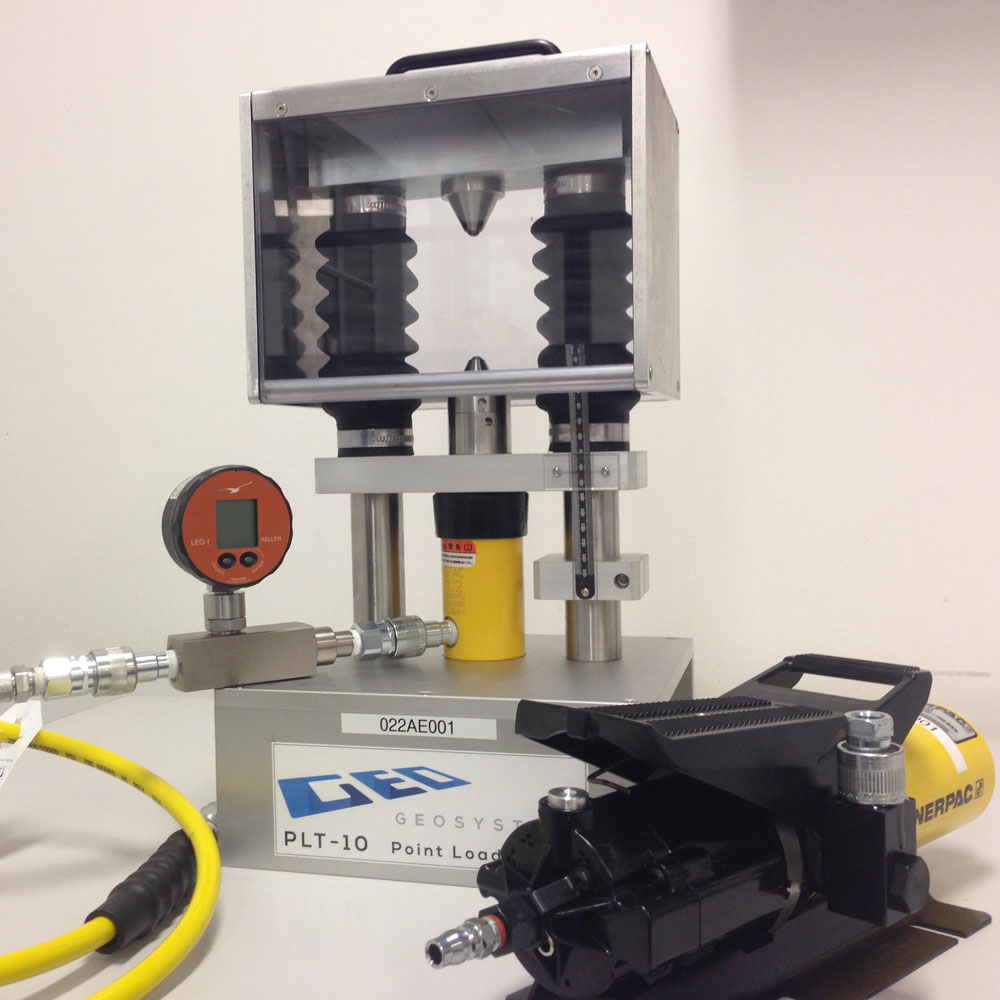

The PLT-10 is designed for automatic pump solutions. However, the PLT-10 is available in a convenient manual hand pump version, ideal for field operations. The extremely rigid test frame remains consistent across all models. The pumps are interchangeable.

Three automatic pump options:

- Mains powered electric hydraulic pump

- Pneumatically hydraulic pump driven by airline or air compressor

- Battery-operated hydraulic pump.

For field applications, the battery-powered hydraulic pump is particularly useful. It is much like a cordless drill where one charges the batteries overnight.

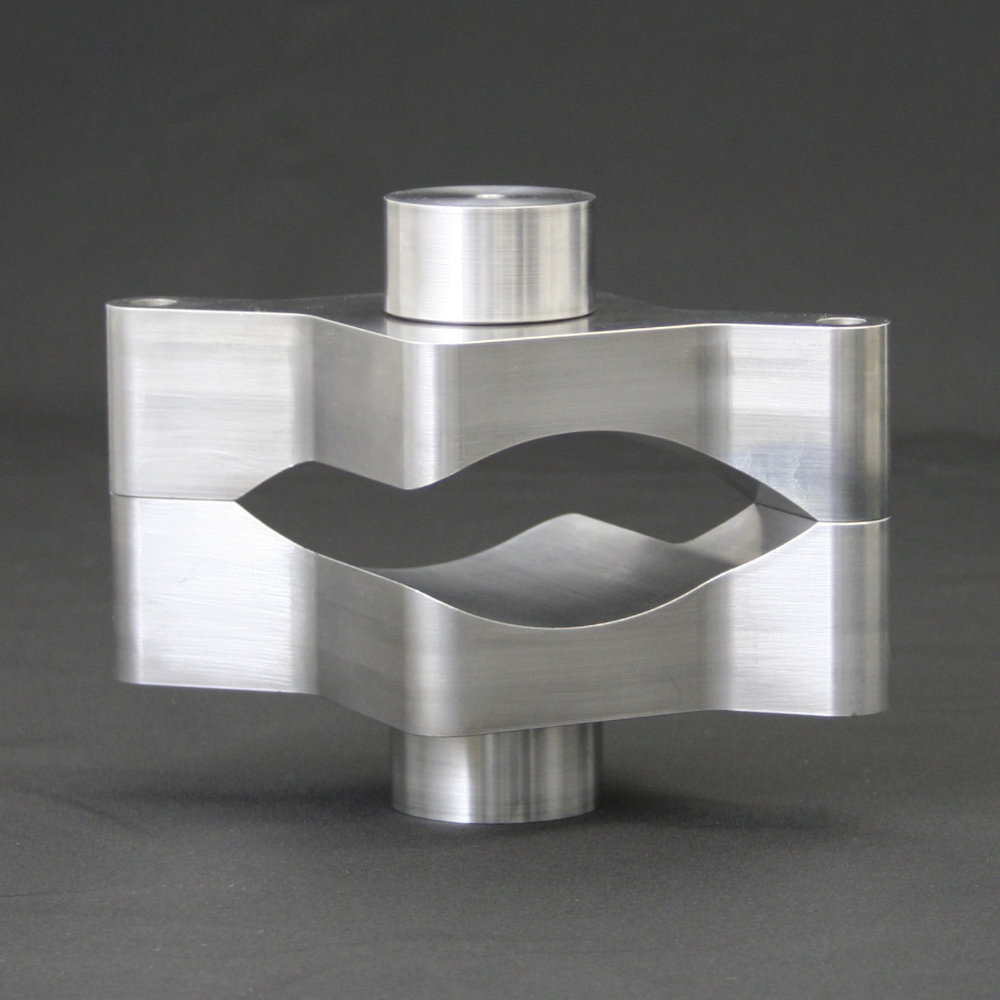

Indirect Tension Testing Brazil/Brazilian Test Platens for determining indirect tensile strength by the Brazil test in accordance with the International Society for Rock Mechanics standard. Self-centering spherical top and bottom seats included.

Unconfined Compression Load Platens – Upper and lower flat platens available

- PLT 10E – comes with an electric hydraulic pump

- PLT 10 – comes with a pneumatically driven hydraulic pump

- PLT 10B – comes with a battery-operated hydraulic pump and two batteries

- PLT 10M – comes with a manual pump

It’s not practical to conduct precise Uniaxial Compressive Strength (UCS) tests on core out of the lab environment. The field practical alternative is to undertake a quick and simple point load test to predict rock strength on the fresh core.

Typically a point load test is performed alongside a drill rig. The alternative is to place the core sample in a core box and send it for lab testing. Modern advances on PLT machinery and transducer have improved accuracy resulting in a very convenient test that is these days undertaken in core sheds and labs. Hundreds of tests per day are often performed in mines. As such, Geosystems developed an automatic machine to avoid arm and elbow injury caused by repetitive cycling.

Safety in mind.

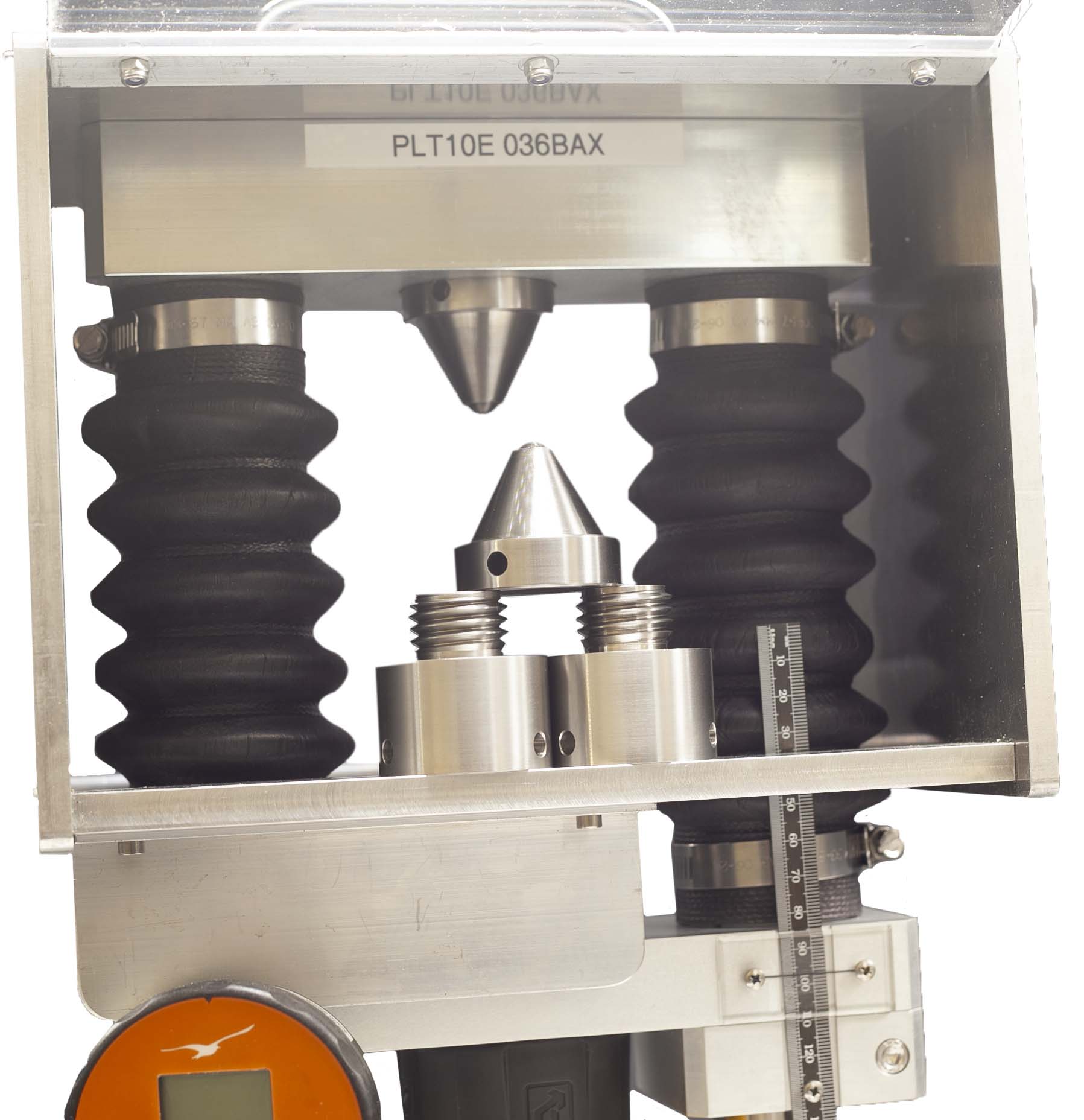

With OH&S in mind, the PLT10 machine is designed to not topple over and features two protective screens on the front-rear to save the operator from injury due to fly rock. A face mask or visor provided with cheap competitive PLT machines proves unsafe. Often protection around the neck area proves inadequate leaving the chest fully exposed. The Geosystems PLT-10 is the safest machine on the market.

In some Australian iron ore projects, the grade is high resulting in a very high strength rock that 50kN or 70kN units cannot cope with. With a rating of up to 10 ton (98kN) loads the PLT-10 is the perfect point load tester for high strength rock tests. The PLT-10 point load tester is perfect to safely determine the point load strength index of rock or concrete core samples.

APPLICATIONS

- Block caving mine

- Open-cut mines

- General civil engineering projects

- Geotechnical ground monitoring solutions

- Slopes

- Bridges

- Lab, and in-situ materials testing.

PLT-10 Downloads and media

DATA SHEET FOR PLT-10 POINT LOAD TESTER

DRILL TO MILL PLANT OPTIMISATION – CLICK TO READ WHITE PAPER

View our explosive fracturing test of a resin core sample.

Watch to see the point load tester power options and functionality.