What piezometer monitoring platform is best for my tailings storage facility (TSF)? Geosystems are often asked this, and as there are several types of piezometers and monitoring platforms, “which piezometer monitoring platform?” is a good question.

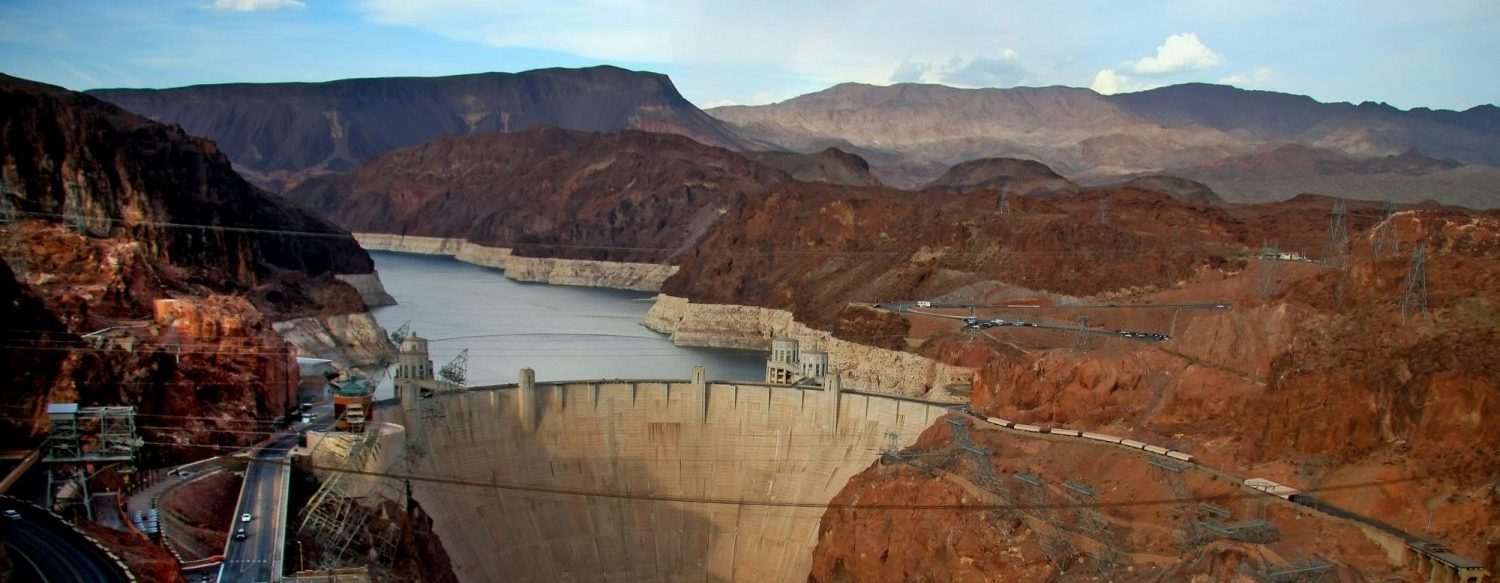

The recent Brumadinho and Samarco tailings dam failures in Brazil have prompted Australian mining companies to undertake audits on their assets such as tailings dams over the past two years. Consequently, the risks of failure have been found to be high to extreme across many mines sites. As a result, more money and time are being spent on the design and monitoring of the structures to ensure Australian lives are not lost.

ESS has seen a steep rise in our Seismic risk assessment consulting work. Through sister company Geosystems, regularly consult with our tailings dam experts on best practices. Concurrently, a methodology to monitor these structures has been developed. It not only monitors the surface but also from within the dam wall structure itself. Once failures are detected at the surface, often it is too late to reverse the problem. This makes mitigation exponentially more difficult and costly. Thus it’s crucial to have sensors such as piezometers inside the TSF structure to detect those first signs.

Monitoring instruments

Monitoring with instruments such as piezometers allows consultants and engineers to verify their design and prove the behaviour of a structure is performing as expected. Sound design practice cannot rely on computer modelling alone, empirical data is critical to feedback real-world observations. Tailings storage facilities are distinctly different from common water storage dam structures. They usually comprise of a series of layered dykes made from compacted soft soil material. These are repeatedly raised as the need for more storage grows. In most cases, the goal is to have liquid in the tailings evaporate via the storage process. However, depending on the nature of the waste or geographical location sometimes evaporation is not possible. As a result, this leads to a very wet and higher risk environment.

In such a scenario water ingress and pore pressure become vitally important to monitor. Often these are the first signs of a flaw and precursors to piping, core breach, and hydrostatic problems overcoming soil friction or material cohesion. These consequent result in imminent dam collapse.

NETWORKED SOLUTIONS

ESS has a suite of data acquisition solutions that can be tailored to TSF geometry and locations. Often TSF’s are located far from offices in remote zones without mains power or communication infrastructure. In this situation, long-range battery-operated wireless systems or cellular solutions are convenient. Geosystems have fitted dams with the more traditional datalogger node and master station approach like the example pictured below. However, we find it a more costly and more resource-hungry design, particularly in data integration and site commissioning. On the bright side, it is a fully networked solution that allows engineers to remotely connect with the network.

Some projects incorporate this configuration. However the downside is it involves modules from several different manufacturers. This demands specialised skills for data logger programming and integration rendering. It a difficult system for the client to maintain themselves. Solar panels are very high in maintenance and often the root cause for network drop outs. They require regular cleaning in what is a very dusty environment. Should they not work efficiently battery damage is possible when the charge/discharge cycle fails.

Roctest

More recently the Roctest LSVW5 battery-operated networked solution has proven more powerful and cost effective offering better value for money. It is very easy to install, configure, commission and maintain requiring virtually no programming or support. It has become a standard solution approach from a data acquisition perspective with only the number of sensors or sensor locations being the only variable. This has enabled greater consistency for our clients with multiple mines or multiple TSF within the same mine. A common approach makes supporting the system at ESS much easier too. It is a system very light on maintenance and isn’t reliant on solar so battery damage is not an issue.

Data is available by browsing to the LSGway using a common web browser and the device has a URL login and is password protected. The data can be downloaded in CSV format for further analysis. The simple architecture is shown below, the Logger node LSVW5 communicates to the LSGWay via long radio and LSGWay via the internal onboard cellular modem allowing the device to connect to the internet.

SMALL NETWORKS

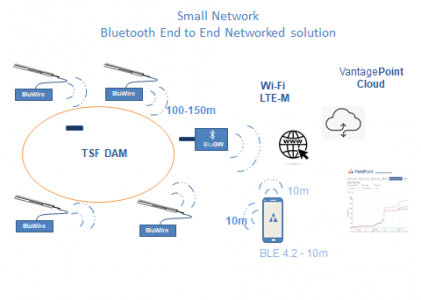

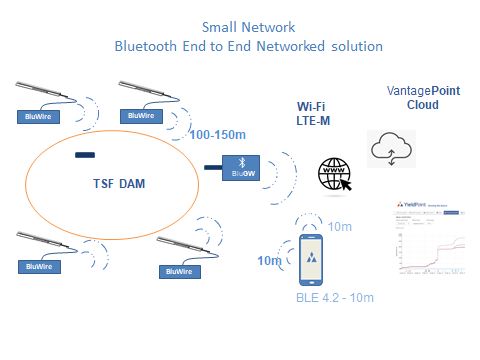

For a tight network around small TSF’s our low cost Bluetooth technology network solution is best suited. The BluWire connects to any vibrating wire piezometer on the market. The BluWire is a four-channel logger that can be networked via the addition of a BluGateway. The logger range to gateway needs to be 150m away. One BluGW can talk to up to 16 BluWire loggers. There is no problem with setting multiple gateways and typically for open pit or surface applications a 4G LTE BluGW is used and a WIFI BluGW for underground. The platform is total plug and play, the gateway scans for nearby loggers and automatically connects. For cellular solutions, mobile coverage is needed, and an active SIM card. For data processing and visualisation ESS offers a cloud service called Vantage or alternatively data can be pushed to a server if preferred.

Following is the simple architecture of the platform.

NON NETWORKED SOLUTIONS

For a client with a TSF with limited life or short mine life a networked solution may be overkill. The limitation of non-networked solution is obviously they don’t offer the alarming or regular automatic upload of data with little latency.

A non -networked solution has latency however if the structure is proven safe there may not be reason for high sampling and regular reporting. In this case we offer a simply the BluWire datalogger with piezometer. One can connect to the BluWire via Bluetooth with android phone or Tablet for data download. The phone APP is free and available on Google Playstore. There is no special proprietary software to communicate with loggers.

Brumadinho failure video

Follow us on LinkedIn to stay up to date with latest developments and products.